The photocopier evolved during the 1960s and was initially a messy liquid and light sensitive process that could make images of printed material. The discovery that a celinium drum would retain an electrostatic charge made the modern copier possible. By 1980 the modern copier was a standard feature of offices and because it was efficient and inexpensive to operate it replace other office and school printing equipment such as the spirit copier and the inky fabric stencil copiers.

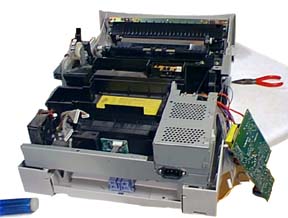

All low priced laser printers are not "Post Script".In the image above right is the primary data circuit board which receives the information from the computer and resident right on that board are the standard fonts set in programming code in some of the chips.

From this board the processed information is sent to the next processing level as seen above left. The image is moved from the green processor card to the laser system while the yellow circuit board provides the laser with the special high voltage power it requires.

Though this is a Apple Select 360 600 dots per inch printer it is typical of other laser printers. Claw your way down to the bottom of the machine and you arrive at the enclosed laser unit. In the image at right you can see the circuit boards have been removed leaving the printers primary power supply on the right and the black compartment containing the optical system housed in its black plastic box with the yellow warning label. The warning label is needed because the laser in a printer if powered up would do permanent damage to human optics if exposure occurred

The original photocopiers did not use lasers to create the images but uses intense light. A laser is "coherent light", light that is at a specific wave length and travels in a discrete parallel beam. Copiers immediately adopted this as their light source as it was easier to control and use.

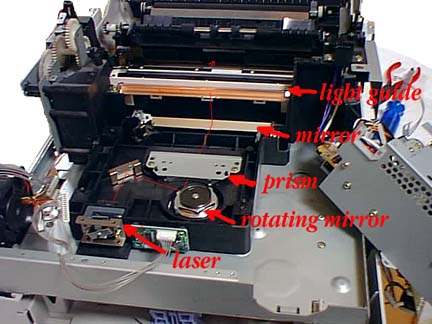

ror onto a rotating mirror which paints

the signal horizontally across the prism placed in front of it. The light emerges

from that prism and reflects off a slightly curved mirror upward where it is bent

through a solid prism light guide and emerges through a glass window.

ror onto a rotating mirror which paints

the signal horizontally across the prism placed in front of it. The light emerges

from that prism and reflects off a slightly curved mirror upward where it is bent

through a solid prism light guide and emerges through a glass window.The whole process relies upon the data flow coming into the the laser regulating the output in terms of intensity. Dot by dot the image is created and flashed through the optics system to the celinium drum in the toner cartridge. Most of the ware and tear on laser printers is to the cartridge and thus it has a limited life of around three thousand copies which seems enormously wasteful as it is discarded when the toner is expended. The other components are remarkably trouble free. The problem that required this repair job was that the printer was operated in a very dusty environment and its fan sucked in fine drywall plaster particles and these were deposited through out the optical system blinding the printers operation. The major issue with repairing it was disassembly and re-assembly, cleaning was a matter of blasting a compress air stream on the optics to clear away the dust. (Do not use vacuum cleaners on electronic equipment, as the air flows into the vacuum cleaner an electrostatic charge builds up on the plastic or metal entry and it can discharge into the electronics destroying microscopic electronic circuits)

The actual high tech nature of the laser printer is not the laser itself but the ton

er. The whole process of the modern copier and the laser printer relies

upon the world of static electricity. The laser beam gives the toner cartridge's

celinium drum a charge and the ultra-fine black powder, we call toner, is picked

up onto the drum as it rotates and then transfers these dust particles to the paper

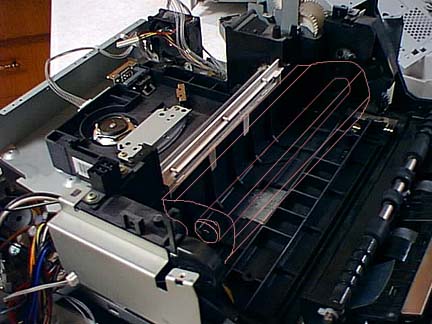

passing by in the printers paper path. In the picture on the right you can see the

laser mechanism from the reverse angle and penciled in is a simple sketch of the

toner cartridge. With the light image coming in from the laser side, the celinium

drum rotates as the paper passes through the roller system on the right imparting

the dust onto the paper which then is passed through the fuser mechanism that is

not shown here but mounts above the cartridge.

er. The whole process of the modern copier and the laser printer relies

upon the world of static electricity. The laser beam gives the toner cartridge's

celinium drum a charge and the ultra-fine black powder, we call toner, is picked

up onto the drum as it rotates and then transfers these dust particles to the paper

passing by in the printers paper path. In the picture on the right you can see the

laser mechanism from the reverse angle and penciled in is a simple sketch of the

toner cartridge. With the light image coming in from the laser side, the celinium

drum rotates as the paper passes through the roller system on the right imparting

the dust onto the paper which then is passed through the fuser mechanism that is

not shown here but mounts above the cartridge.The toner is a combination of carbon and plastic particles, when it passes through the fuser mechanism the paper and the dust is momentarily heated, melting the plastic and bonding the carbon to the paper's fibres. Everyone knows that when you jam a copier or printer and removed the paper that hasn't made it through this stage of the machine, the image on the paper can be shaken or rubbed off.

So there you have it, the inner life of a laser printer, or for that matter of a copier, which works along the same principle only the copier takes and creates its own input by scanning a document then replicating what it scanned on the copy. Inkjet printers are a whole different process, related as stated earlier, to the old dot matrix process of printing and perhaps some day I will get to tell you how they work.