|

| FTLComm - Tisdale - July 21, 2000 |

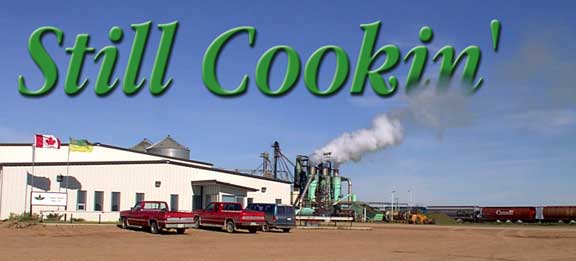

The alfalfa dehydration industry has undergone a major restructuring during the past

few months as Parkland, a small plant near Alysham and the Hudson Bay plants all

have ceased production. The reduced Asian market has been the most commonly sited

factor for the down turn but no doubt there are other more direct problems affecting

the business. Not the least of which is the fact that natural gas used to dry the

alfalfa to make pellets or cubes is now costing the processors double what it was

just a year ago. With this remarkable input cost alone trampling on lower demands it is remarkable that any of the Western Canadian plants are still in production. In the picture on the right we see fresh field alfalfa being piled up for processing at the cubing portion of the plant. Tisdale Dehydration has been able to shuffle its producers this year as some of the choice producers from Parkland have signed on while some lower grade production farmland have been dropped. From St. Brieux to Porcupine Plain and almost to Nipawin the Tisdale trucks are on the road bringing in this year's first cut. The low temperatures have drastically reduced this years hay production as they were held back nearly two weeks from starting the season and by this time other years they would be nearly finished the second cut. This year the first cut is still not finished and there will be only two times round the fields this year. However, with a smaller crop the attention to quality is much greater and working with the lab in town the plant and field harvesting are concentrating on bringing in the best product with the highest food value possible to improve the price and satisfy customer demand for ever better alfalfa. |

|