Thinking an idea through, laying out a design and then turning it into a real object has always been a part of human development but the way we do that today is changing rapidly. Almost three years ago Andrew and I conceived the idea of using simple plastic ABS plumbing pipe to make light weight durable structures. Our first project was an office and mobile computer desk which we still use today.

Andrew

and Timothy Jr. frequently have been involved in various trade shows as presenters

or visitors and with a upcoming trade show in mind Andrew set about designing a booth

that would be highly visible and yet inexpensive, light weight and would serve to

represent a company well. Trade show display structures are usually priced in the

tens of thousands of dollars so this project is remarkable as its materials cost

less then $500.

Andrew

and Timothy Jr. frequently have been involved in various trade shows as presenters

or visitors and with a upcoming trade show in mind Andrew set about designing a booth

that would be highly visible and yet inexpensive, light weight and would serve to

represent a company well. Trade show display structures are usually priced in the

tens of thousands of dollars so this project is remarkable as its materials cost

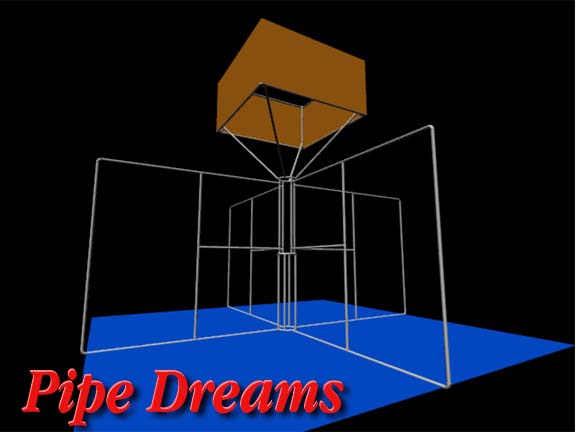

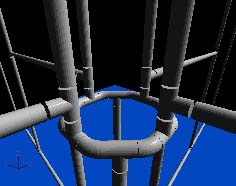

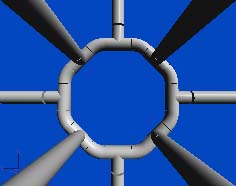

less then $500.But first here is how the project evolved. The conceptual design above was done using the modeling software Infinity-D which allows you to put parts together in a three dimensional environment then render it so that it can be view from various angles. Using the parametres of 1.5in ABS plumbing pipe and connections Andrew and Tim created the image above. The central core with four extension wings out from the core and a sign holder well above the unit. Getting the parts to fit in the manner planned is sometimes as difficult on the computer as it is in real life. The main element of the design is the combination of elbows and "Ts" to form the basic starting point in the centre.

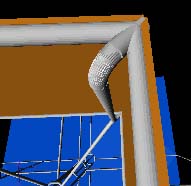

sign

display box presented some special problems as you want the corners to be clearly

defined and yet still give room for the coroplast signage and a place to install

the lights. This part of the display booth involved the creation of some creative

use of the parts available to create the desired product. The image at the right

shows how that corner was achieved looking from above while the image on the left

has the same corner at the bottom of the sign display.

sign

display box presented some special problems as you want the corners to be clearly

defined and yet still give room for the coroplast signage and a place to install

the lights. This part of the display booth involved the creation of some creative

use of the parts available to create the desired product. The image at the right

shows how that corner was achieved looking from above while the image on the left

has the same corner at the bottom of the sign display.

Getting the sign up above the competing booths is one of the main problems at a trade show. The idea is to attract attention to the booth and appear to command the display area. Andrew attacked the sign situation by put that sign well above the booth itself and making it big. Of course this presents some stability and strength issues because plastic pipe is light it has a low level of longitudinal strength and tends to flex. On the right is how the sign is affixed to the central core. When they turned the design from a computer generated object to the real thing there was a need to add some strength to the sign position and this was done easily with minor connectors to the wings.

So that the project can be assembled and disassembled for storage and reuse the joints are put together using pop rivets and the real thing and the design model mirror one another.

The interesting thing about this project is that the whole thing was fabricated in software, then rendered and presented to management as a design and approved at that state, then the materials were acquired and the project constructed right from the computerised representation. This method of design and production has become common place in industry today. It is sometimes referred to as CAD (Computer Assisted Design) but that is really an over simplification because with the software now available the engineering aspect of the project is much less in the forefront as the designer can concentrate on form and aesthetic design and work directly from the model with it being merely a simulation of the real thing. As you can see from these pictures the real thing and the design work reflect each other and working with such simple materials means that the construction work is the easier of the two parts of the project.

It was decided during construction that the booth would be more effect without the extra five foot outward extensions on the wings and they have not been included in the final produced project.

Taking an idea and turning it into reality is one of the pure achievements a person can experience. We so often get so involved with the notion that we need specific hardware, software and tools to get a project underway when in fact we really only need to work on the skills we already have at hand and go with the strength of those skills. Andrew has spent considerable time making things with Infinity-D which is essentially an art rather then technical drawing product yet he was with Tim's help able to use the software he had to produce a detailed construct model and from that the real thing. Congratulations Andrew and Tim.