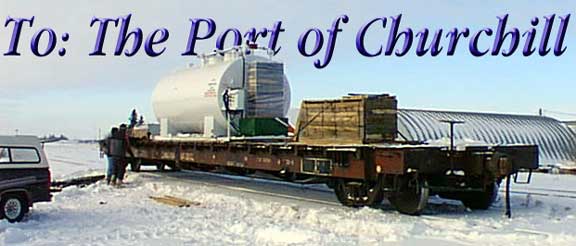

Complete turnkey system is almost ready for the long trip up the line through Thompson and on to Churchill. This system is a two compartment system with Diesel and gasoline with all its pumps and merely needs to be set in place and the electrical connections made. Northern Steel Industries turns out systems like this almost on a daily basis but this one is unusal simply because it is being shipped by rail rather then by truck.

It does not seem so very long ago when this was the main method of shipping all things but in the last three decades

shipping

by rail has become

shipping

by rail has becomean oddity. The various components to this system have been crated and fixed onto the flat car with still about a day's work left to make it ready to ship. This loading process on a truck would take much less then an hour but it takes nearly half a day of telephone calls to just arrange for this car then once loaded a CN representative must drive over from Humboldt to inspect the load.

When the railroads were useful this process would have been handled by the station agent who would arrange for the car, loading time and would see to the inspection of the load, then handle all the billing and paper work that would be required. Those days of efficient inexpensive shipping methods are now merely something old guys talk about.

In order to be safely loaded on a flat bed the load must be able to sustain a six mile an hour impact as the energy transfer during hitching and accelleration can reach that limit. This means this tank will have additional tie-downs to secure it to the rail car before it is ready for movement to Canada's arctic.