|

Production |

| FTLComm - Tisdale/Winnipeg - January 28, 2001 |

While Northern Steel is assembling and shipping everything that it can make as quick as possible, the orders keep pouring in, but this company aggressively wants always to improve itself and spends a lot of money on research and development as new products are being developed. Once a product is made and tested, its time to take it to the marketplace. Last year Northern Steel developed an outstanding automated system for selling liquid fertilizer and now they are in the midst of a their campaign to sell these outstanding and complex systems. To market this product Northern Steel came to FTLComm to help them put together a video that can be used at trade shows and sent off to customers showing off the features of their new Auto-Blend system. Using animation and still photographs FTLComm |

and their partner,

Midcan in and their partner,

Midcan inWinnipeg, this production was undertaken. The key to success in a project like this is having talented and creative people to make ideas come into reality. Brad Haplock is one such remarkable individual an artist, designer and animator working at Midcan developed the Northern Steel animated logo to launch the project then constructed in about eight hours a virtual three dimensional model of the Auto-blend system that can be manipulated on screen and was animated to give the viewer a full view of the concept. |

Using an SGI computer specifically designed for this kind of work he put the system together on screen simply from using pictures and drawings of the actual system. The wire frame model could then have textured surfaces applied and then is lit with the sort of lighting that would occur in a real site. Once the elements are created the computer goes to work rendering the images, frame after frame to create the animated sequences, this process is completely done by the computer and its programme but requires many hours to complete depending on the length of each animated |

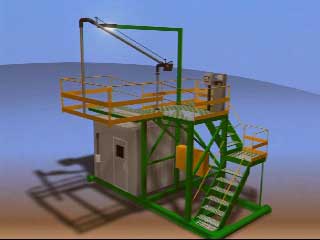

sequence. sequence.These smaller pictures on this page are actual screen captures from the completed video and illustrate the details that appear on the video screen. This image rotates on the screen giving the viewer a 280º look at the system as it changes from this high shot to a low angle from the left and in each frame the shadows remain where they are suppose to be relevant to the lighting established for that sequence of images. To bring the video to life there is a music background track and a Winnipeg Radio announcer reads the script that tells about the Auto-Blend system. As with all animated projects the script was prepared from a point list, a sequence of images was created to make a story board. Then the narrator came into MidCan's studio and recorded the script. The images to be used with the script were |

assembled

and modified to assembled

and modified tofit the project. With the parts ready to be put in place the digital images were then placed in sequence with the narration in this editing suite using the same kind of off-line editing software and equipment used to create a full feature Hollywood motion picture. AVID software is used to produce the complex blends and spices the image to image in timed with the narration. Andrew Shire was the editor on this project as he organised the material creating the actual video. In this picture you can see the storyboard/script laying in the foreground on the desk. |

The animated sequences were blocked out in time in the project as they were among the last components to be added. Andrew is seen here as Brad set the animation process into motion. One of the few PCs in this office complex appears in this picture where it is used as an image server. The computer on the left hand side of the screen is one of several Macintosh G4 machines used in this office for creating multimedia productions, cutting CDs and DVDs. This actual production for Northern Steel, though a video was encoded on one of these machines then transferred to a disk image, shipped via the Internet to Tisdale to be |

burned

onto a CD. burned

onto a CD.The video tells the story of the automated fertilizer handling system and at the heart of the system are these components including the mass flow meter and the stainless steel filtration system that measure out and regulate the precise amount of various types of fertilizer creating a blend specifically designed for the field application required for a specific plot of land. Northern Steel really did their homework with this project as they have something that automatically can do what in a manual operation can take a highly skilled operator and a lot of calculations to produce accurate results. With the Auto-Blend system the whole process is accomplished by the computer operated facility and can do its work directly for the customer with no one there to sell the product to him, the automated machine can do the task all on its own. |

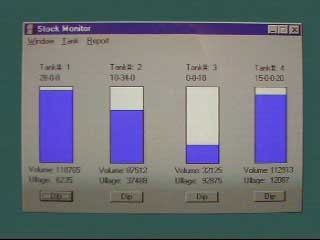

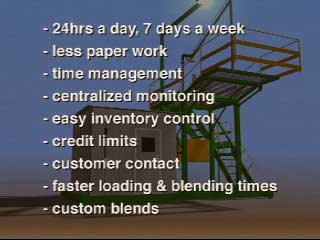

Integral of the Auto-Blend system is the software that controls the blending process and regulates the accounts of the customers using card reading equipment and to make it even more efficient the whole system is centrally controlled by the selling company from a central office using telephone connections to the computer controlled dispensing system. From their office they can monitor the sales, maintain inventory and customise customer accounts. Farmer have their fields tested and the results are entered into the system so that upon picking up their fertilizer they input the identification of the field the product is going to and the blend is create specifically for that field. |

Northern Steel makes the tanks and assembles the entire system so that it can be a complete system for the fertilizer seller or the Auto-Blend system can be retrofitted on earlier systems already in place. Building comprehensive fully integrated systems is one of the achievements that is distinguishing Northern Steel from other tank manufacturers as Northern Steel has a tendency to put things together right and become their customer's one stop shop for tanks and all the accessories that go with the products. The Auto-Blend system is just one of many complete turnkey projects that rolls off the Northern Steel assembly line along with fully self-contained aviation fueling systems, complete service station tanks-bowser and light systems, fully automated fuel cardlock operations, all are part of Northern Steel's whole system approach to manufacturing. |

This shot of the Auto-blend system was not actually animated in the video but involved two images one showing the system during the late day and the other after dark, then in the editing process the two images combine creating the illusion of seeing day turn to night. Using a digitally created animation has some really important advantages as you can produce a scene in a video that replicates reality but can be done with equipment or situation that are to costly to film or weather and time simply make it impossible to create that setting. With the animation and the three dimensional model the realistic setting can be simulated and the concepts associated with it conveyed to the viewer. The viewer is increasingly becoming more image literate and they can see what the illustration is showing as they become more and more familiar with seeing rendered simulated settings. |

The final video is less than four minutes in length and encapsulates the important features of the product. Both as a demonstration tool or as advertising material to hand and send out to a customer, the video fits nicely on a small 3.5in CD. Northern Steel is not only innovative in their approach to production of tanks and accessories but in selling their products they are not afraid to break new ground and try new ways to getting their story told. They provide their prospective customers with a large ring binder with illustrations and information on their products but also have that same material available as a html project on a CD. Both the video and the binder converted to CD are productions of FTLComm in association with MidCan of Winnipeg. |