|

|

|

Gassification: the Ultimate Renewable Resource |

|

| Brendarin Farms - Tuesday, December 18, 2001 by: Edwin Wallace | |

|

renewable |

This is a story of how my dream of having a truly efficient, renewable, alternate source of energy on our farm came about. |

|

|

|

|

Don |

It all started early this fall when my friend Don Francis, of Mantario, Saskatchewan, flew his home built "Cubby" over here for a visit. Don has built about five or six planes from plans alone and kits and is currently putting the finishing touches on an RV8. He is the builderís builder; his planes are perfectly crafted in every sense of the word. I mention this because Don has acquired a quite a sizeable number of interesting friends interested in things mechanical. |

|

|

|

|

Willie |

One of those is Willie Mollenbeck of St. Gregor, Saskatchewan. During the course of our visit, Don, told me that Willie was working on what he called a gasifier - Willie planned to heat his whole farmyard complex which is replete with a very large shop. Immediately I was quite excited about that, since I had researched gasifiers some years ago and saw the merit, but never got round to doing anything about it. |

|

|

|

|

research |

Following a very good visit and after Donís departure I immediately went to the "WEB" to renew my earlier research. A get-started source of information is "The GenGas Pages". There is a discussion of the theory (Not so good) and more importantly a description of how to build a "Downdraft Gasifier". (Also not so good but the basics are there.) |

| The Principle Phases are: | |

|

heat |

|

|

|

|

|

250% |

You might already see that we are getting the heat from more fuel than just the wood chips alone. It is estimated that gasification increases the heat output of a given amount of wood by 250%! |

|

|

|

|

fire |

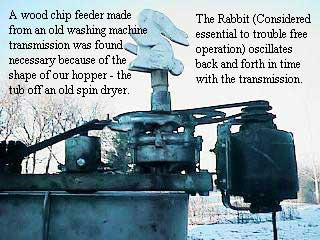

Armed with the theory and a general idea of how we might proceed, my son Darren, and I scoured our farmstead looking for junk that might work. We needed a fire tube or a "stack" which would be about 16 inches long and 6" in diameter with a good wall thickness. We required a large cylinder to house the fire tube; a hopper of some kind to hold the fuel and an air pump to supply the down draft. |

|

|

|

|

car air |

We were fortunate. We had material for the stack and an old 100# propane cylinder to hold the stack. We used an air pump off a 70s vintage auto engine for the air pump. Then we realised we would have to cool the gas before it got to the pump; a collection of auger tubes and a barrel did the trick. When we got it all stuck together it looked like this. |

|

|

|

|

|

gassifier -- |

|

|

|

|

clean |

Of course the intent was to get a useable gas fuel from all of this. You canít imagine how happy we were to see the first clean burning flame from our burner. (Willie and his son Kevin flew down to our place in his 172 when he heard we had a real, live, 100%-gas-producing, gasifier doing it's thing on our farm. It is great fun to see grown men literally dancing with joy.) Darren and I have a lot of fun while engaged in our "Projects". A little whimsy was at play when Darren decided our gasifier needed a mascot. During the second world war it is estimated there were a million gasifiers running automobiles world wide. Nothing like that here in North America; we have always had enough fuel to spoil us. The down draft gasifiers of that day used the vacuum from the car engine to provide the necessary flow of air. We may eventually run a gas or diesel engine and an alternator to produce electricity but for the first application we are going to use the gas to heat water which we will circulate in a hot water system for the house and shop etc. So we had to have an air pump. Such a pump as was found on car engines back in the 70s does the job very well. There are many more details of course but they would make this story much too long. |

|

chipper |

We have constructed a wood chipper but I will not go into detail about that here either. Rather, I would like to talk about what I see as the possibilities for gasification of biomass. In countries such as Sweden, willows are coppiced (grown in high concentration) and provide an endless source of fuel for community owned gasifiers. A firm in Sherbrook, Quebec is in the process of setting up a plant that will gasify not only wood, but other municipal waste as well. |

|

|

|

|

waste |

As I think about all the deadfall and scrub bush that could be harvested in Saskatchewan, and never touch the merchantable timber, I am overwhelmed at the scope of the possibilities. Here on our farm, our caragana hedges provide enough deadfall and pruning to give us a lifetime of fuel - and longer, it is always being renewed! This causes me to ask seriously, must we always be slaves of the oil and gas companies. Our little project here on Brendaren Farm will undergo some modification and streamlining this winter and then will become our major source of warmth next winter. I invite others to experiment with this exceptionally efficient system. |